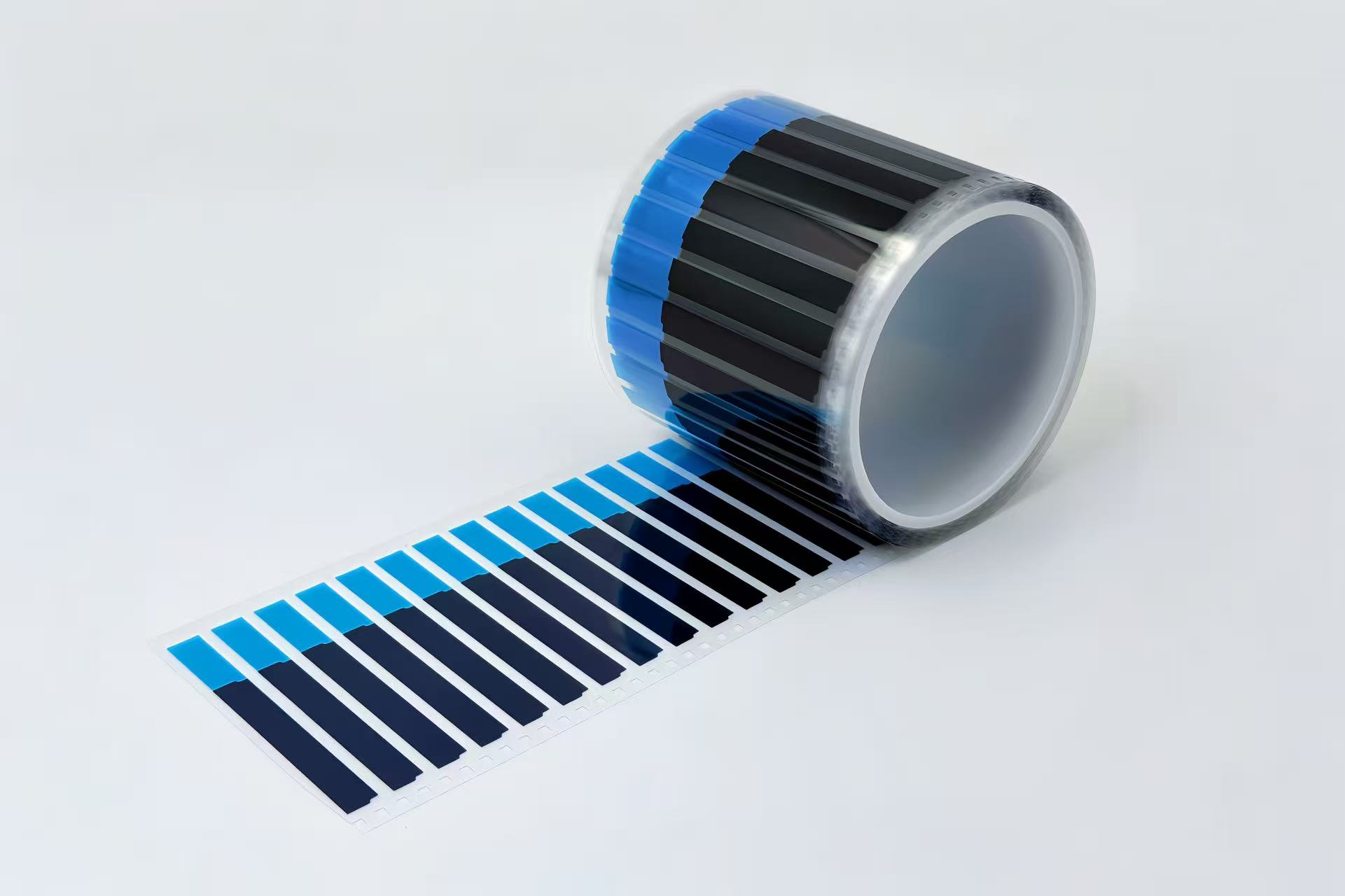

Product Introduction:

Conductive tape die - cutting is a precision manufacturing process that cuts rolled conductive tape materials into specific shapes and sizes through molds. This process is very common in industries such as electronics, telecommunications, automotive, and medical equipment, and is used to manufacture electromagnetic shielding (EMI) gaskets, grounding pads, conductive connectors, sensor contacts, and flexible circuit components.

Product Features:

● High - precision and complex shape realization ability: Precision knife molds (laser knife molds/etching knife molds) can cut complex patterns with a tolerance of ±0.05mm or even higher (such as fine meshes, micro - contacts, and irregular contours), meeting the stringent requirements of modern miniaturized electronic components.

● High - efficiency and mass - production advantages: High - speed continuous production, with the speed of the rotary die - cutting machine reaching dozens of meters per minute, and thousands of small parts can be produced per minute. Automated integration, the die - cutting process is easy to integrate with processes such as automatic unwinding, visual alignment, on - line inspection, and automatic rewinding/stacking, realizing full - process automation, reducing manual intervention, and improving consistency and production capacity.

● Excellent product consistency and quality stability: Batch consistency, the mold ensures that the shape and size of each cutting unit are highly consistent, avoiding manual errors. Controllable edge quality, sharp cutting edges and optimized parameters can reduce the risks of burrs (especially for metal foil layers), glue overflow, and delamination, improving the electrical safety and reliability of the product. The pure physical cutting process does not generate heat, avoiding material deformation or performance degradation due to heat (especially for heat - sensitive adhesives or polymer substrates).

● High material utilization & significant cost - effectiveness: Through intelligent layo

Telephone:+86 15359283152

Email:Marketing@neogor.com

Address:No. 5, Fangshan South Road, Xiang'an District, Xiamen, Fujian Province, China.